Time:2025-03-20

Sapphire glass, as a high-performance and high hardness optical material, has a wide range of applications in fields such as watch mirrors, mobile phone screens, and optical components. The preparation process involves multiple precise steps, from the selection and melting of raw materials to subsequent cutting, polishing, and strengthening treatments, each step is crucial. This article will introduce the preparation steps of sapphire glass, providing readers with an in-depth understanding.

1、 Raw material selection and melting

The main raw material for sapphire glass is high-purity aluminum oxide (Al ? O3), which is specially treated to form a stable crystal structure at high temperatures. In the preparation process, in addition to alumina, a small amount of other oxides such as lanthanum oxide, yttrium oxide, etc. need to be added to adjust certain physical and chemical properties. These raw materials need to undergo strict screening and proportioning before melting to ensure the quality and performance of the product.

Melting is a crucial step in preparation, where the raw materials are placed in a high-temperature furnace, typically controlled above 2000 ℃, to ensure complete melting and formation of a uniform melt of alumina and other oxides. During the melting process, it is necessary to strictly control the temperature and melting time to avoid impurities and defects. After melting, the melt will quickly cool and solidify into cylindrical or square crystal rods, which is the initial form of artificial sapphire glass.

2、 Cutting and Grinding

The sapphire crystal rod obtained by melting needs to be cut and ground to form the desired shape and size. Cutting is usually carried out using laser cutting machines, which can precisely control the cutting depth and position, ensuring that the cut sapphire glass sheet has a flat surface and precise dimensions. During the cutting process, some scraps and debris will be generated, which need to be properly handled and recycled.

Grinding is the next step after cutting, aimed at removing burrs and uneven surfaces generated during the cutting process. The grinding process is usually carried out using a grinder and grinding solution, repeatedly grinding the sapphire glass sheet through the upper and lower grinding discs in the machine until its surface becomes smooth and flat. During the grinding process, it is necessary to regularly replace the grinding disc and grinding solution to ensure the grinding effect and product quality.

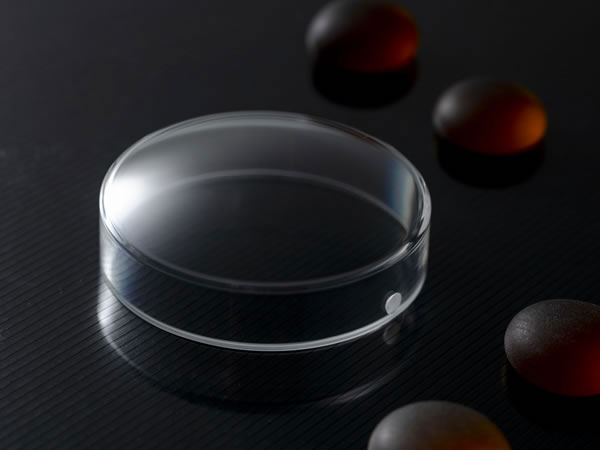

3、 Polishing and Cleaning

After grinding, it needs to be polished to further improve its surface smoothness and transparency. The polishing process is similar to grinding, but the polishing solution and polishing disc used are more refined. After polishing, the surface of sapphire glass will form a uniform mirror gloss, making it look brighter and clearer.

After polishing, cleaning treatment is required to remove stains and residues generated during the polishing process. Cleaning is usually carried out using ultrasonic cleaning machines, which can use small bubbles generated by high-frequency vibration to deeply clean sapphire glass sheets, ensuring that their surfaces are clean and free of stains. During the cleaning process, it is necessary to strictly control the cleaning time and temperature to avoid damage.

4、 Physical reinforcement

In order to improve hardness and impact resistance, physical strengthening treatment is usually required. The principle of physical strengthening is to heat sapphire glass sheets to a certain temperature and rapidly cool them, causing uneven stress distribution inside, thereby improving their hardness and toughness. During the strengthening process, it is necessary to strictly control the heating temperature and cooling rate to ensure the strengthening effect and product quality.

5、 Testing and Quality Control

In the preparation process of sapphire glass, strict quality control and testing are required at every step. Regular sampling and performance testing are required from the selection and melting of raw materials to various steps such as cutting, grinding, polishing, cleaning, strengthening, coating, and laminating. These tests include optical performance testing, structural performance testing, hardness testing, impact resistance testing, etc., to ensure that the quality and performance of the product meet customer requirements and industry standards.

In addition, it is necessary to strictly control the environment during the production process, including factors such as temperature, humidity, dust, etc., to avoid adverse effects on quality and performance. Through strict quality control and testing, it can be ensured that every batch of sapphire glass products has stable quality and performance.

Sapphire glass has a wide range of applications in fields such as watch mirrors, mobile phone screens, optical components, etc. due to its excellent properties such as high hardness, high transparency, high wear resistance, and high chemical stability. The preparation process involves multiple precise steps and strict quality control. By continuously optimizing the preparation process and improving product quality, sapphire glass will demonstrate its performance and broad application prospects in more fields.

Tel

Mobile phone

Customer service

TOP